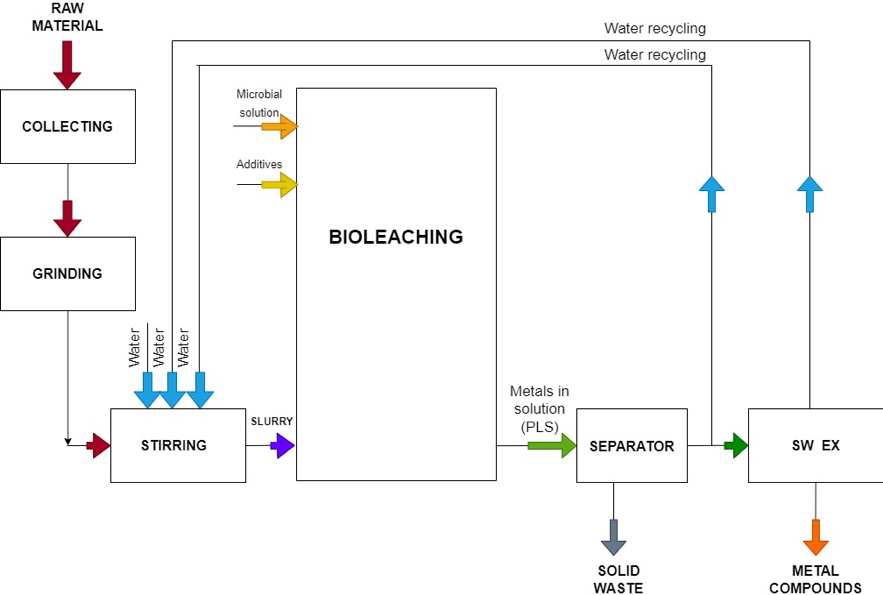

Combining novel different steps of bio-treatment in most efficient order, the whole process enables reaching yields as high as 99% quickly, produces neutral wastes and circularizes the use of water and industrial tailings. Every step of biotreatment is using different mixture of micro-organisms at different conditions, making it possible to reach yield values 86–99% for various resources which is 15-25% higher than the yield rates from traditional methods (60-80%). The process works for a wide range of low-grade ores/wastes including Black Shale, Phosphogypsum, Bauxite Residues, Waste Electronic Equipment etc.

Different tailings and polluted water can be used as feed for micro-organisms in given novel process, resulting efficient remediation while reducing the dependence on traditional energy-and resource-intensive metal extraction methods.

Back in 2010, we at BiotaTec performed trial bioleaching tests with Graptolite Argillite. We were especially interested in extracting Vanadium, Rhenium and Molybdenium.

Due to fascinating results, we carried out a further investigation that resulted in a vision of a combined method for the degradation of organic geopolymers and bioleaching of metals from given Estonian black shale. In a given approach, specially developed consortia of microorganisms produce methane gas in anaerobic phase at neutral pH while simultaneously freeing metals through degradation of organic complexes.

We named the technology BiotaMet, and we started to adapt the microbial consortia to work with very different low grade raw materials. 5 years long research resulted with a patent application in 2016 and PCT in 2017.

The approach of BiotaMet can be adapted for any organics and metallic complexes containing ore or mining waste that is considered not valuable for processing with less profitable traditional technologies or common bioleaching at acidic conditions. Through the generation of methane gas as energy source, the whole process would be more cost-efficient, by breaking up the organic complexes more valuable metals would be extracted and the solid waste of would be more environmentally friendly.